Self-control and automation

Jinzong Automation

Automation is a machine, system or process (production, management process) with the direct participation of no one or few people, according to human requirements, through automatic detection, information processing, analysis and judgment, manipulation control, to achieve The process of the expected goal.

Human-machine integration

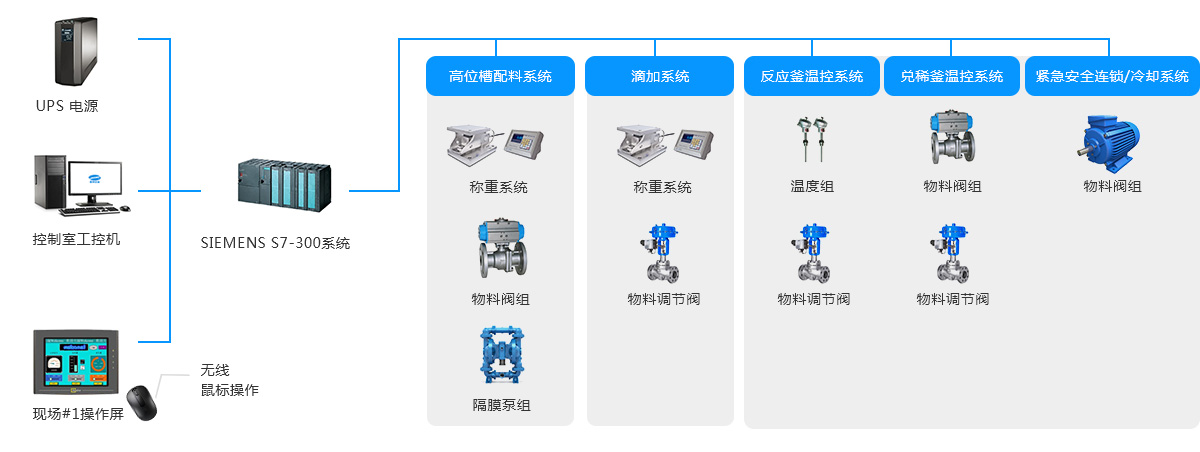

System integration: industrial computers, PLCs, displays, operating systems, automatic valves and process lines

Process setting: process parameters and process can be preset

Parameter adjustment: online adjustment and correction can be performed at any time

Data storage: can store relevant data in the production process, easy to check

Parallel network connection: can be connected with engineering computer network to realize remote monitoring and management

Man-machine interface: control of each process, the operator can complete in the control room, click the mouse

Security alarm: automatic alarm, safe production, foolproof

High efficiency and high energy: saving a lot of manpower and material resources, improving product quality and reducing production costs

Accurate measurement

The PLC control system calculates the flow rate or weight change rate according to the real-time data of the automatic feeding process control, and precisely controls the material addition speed and accuracy according to the change rate PID algorithm closed-loop control valve opening degree.

Pneumatic diaphragm pump

Weighing module installation site

Accurate temperature control

The PLC control system calculates the flow rate or weight change rate according to the real-time data of the automatic feeding process control, and precisely controls the material addition speed and accuracy according to the change rate PID algorithm closed-loop control valve opening degree.

Safe and efficient

The PLC control system sets the high temperature alarm and emergency plan function. When the first limit automatic control occurs unexpectedly, it quickly rises to the second limit, and immediately cuts into the emergency automatic processing according to the plan, and simultaneously alarms to remind the operator to intervene and process to ensure the production. Absolute security.

Electrical control

Proportional valve

Weighing

Weighing is the key to the entire production process, and it is also a difficult point for long-term constraints on how to eliminate potential risks and improve efficiency.

①electronic prescription

• Ensure that weighing personnel perform weighing operations in strict accordance with the prescription to prevent final product quality deviation caused by weighing error, resulting in higher production costs.

• Prevent misfed raw materials.

• Guaranteed weighing within tolerances.

electronic prescription①

electronic prescription②

②accurate online weighing

• Based on the posted work orders and visible weighing tasks, materials can be prepared in advance to increase material handling efficiency.

• Graphical weighing electronic command, efficient process control, the system guides the operator to complete the prescription weighing step by step, making the weighing process simple, fast and accurate.

• Scale management, automatically determine whether the scale is in the calibrated state during weighing.

• Scan the review material before weighing to automatically determine whether the batch is qualified and avoid the risk of material expiration.

Online weighing ①

Online weighing②

③automatically generate weighing records

• Let the producer concentrate on the weighing operation and the system automatically records the weighing data. Prevent post-manual statistical errors.

Automatic generation of weighing records ①

Automatic generation of weighing records②

④ mobile feeding

• Automatic review before feeding to prevent the risk of mixed batches.

• Feeding becomes more controllable and simple.

• Material identification is available in production rooms where wireless signals are present.

⑤ mobile report terminal

• Managers can query real-time production schedules, production anomalies, and view production reports at any time and any place through the mobile terminal.

⑥ full traceability

• The system automatically records weighing and dosing process data during the production process, providing production records and audit trail data to make traceability faster.

⑦ production full-process material barcode scanning

• All materials are barcoded, and one-click scanning is performed during weighing and feeding to prevent material errors.

Avoid the risk of manual identification.

⑧ scalable system architecture

• Weighing and batching systems can be linked to other systems such as ERP, production systems, warehouse management systems, and automatically collect data.